Basic Member

Get a free quote or proposal for

Vacuum Press Rolls

DESCRIPTION: |

|

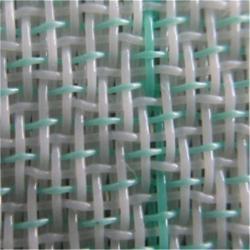

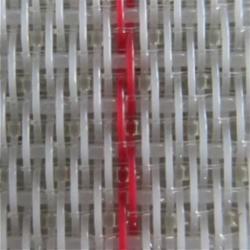

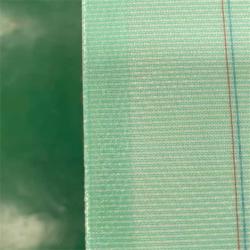

Vacuum press roll is mostly used in medium and high-speed paper machines. The upper roller of the vacuum press is a stone roller, and the lower roller is a vacuum roller. The structure of the vacuum roller is basically the same as that of the vacuum couch roll. The roll shell is made of bronze or stainless steel, and the thickness of the shell is determined by the required stiffness and strength. Other working parameters of the paper machine, such as speed and vacuum degree, remain unchanged. The thicker the roll shell is, the smaller the dewatering capacity is. In high-speed papermaking, the moisture in the blanket and wet paper is sucked out, passes through the eyelet on the roller, and then turns around the vacuum suction area before being thrown into the white water pan by the centrifugal force of the roller. The function of the vacuum chamber is only used to suck the air into the hole of the shell. The thicker the roller shell is, the more the volume of air is pumped. Therefore, the vacuum roller with a thin shell made of high-strength metal is beneficial to improve the press dehydration efficiency. Specifications: 1. Suction press roll can remove more water from wet paper, increase the sensitivity of paper and compare with an ordinary roller, and the paper is less crushed. 2. Shell Material: Iron Cast/Steel plate rolling. 3.Shaft: cast steel/45#40Cr/42CrMo. 4. Roll face cover: Rubber or Polyethylenelene. Advantages: 1. Excellent runnability due to high vibration absorption behavior 2. Optimal dewatering due to very strong mechanical properties leading to highest 3. Shortest drainage time due to tailor-made surface design (Surface Manager) 4.Very limited energy losses(driving and pressing)due to very low heat buildup 5. Longest nip pressing stability in operation due to the fact that the cover has no 6. Less risk of open area contamination due to surface self-cleaning properties continuous 80°C/ peak 110°℃ 7. Longest dewatering stability due to highest Nip & Peak Pressure stability 8. Long lifetime due to excellent abrasion resistance without hydrolysis 9. Long resistance vs stress due to high-performance bonding system |

|

COMMERCIAL DETAILS: |

|

| Min Order Qty. | 1 Piece |

| Avg. Lead Time | 30 Days |

| FOB Price * | US$3000 / Piece |

| Payment Options | L/C, T/T |

| Payment Terms | 100% in advance |

| Country of Origin | China |

| Shipping Port | Beijing, Tianjin, Qingdao |

MORE DETAILS: |

|

| Product Condition | New |

| Model No. or Name | HT-27 |

| Brand Name | Huatao |

| Supply Capacity | 30 Pieces / Month |

| Packaging | Wooden box |

| Sample Offered? | Not Applicable |

| * Prices are subject to change. Please contact the supplier for the latest price. | |

Mr. Maple Zhao

CEO, Huatao Lover Ltd.

Member Since: Aug 2022

Response Rate

9%

Location ![]()

| Address Line1 | No. 298 Zhonghua North Street |

| City | Shijiazhuang |

| Postal Code | 050000 |

| District / County | Xinhua |

| State | Hebei |

| Country | China (Mainland) |

| Region | East Asia |

Product Listings

by Huatao Lover Ltd.

Find More Products in These Categories

More Product Listings

Looking for Buyers Instead?

Press Rolls Buyers from around the world

_1908220074302.jpg)

_1808220153952.jpg)

_1808220153953.jpg)

_1908220135038.jpeg)

_1908220135039.jpg)

_1908220135041.jpg)

_2208220143514.jpg)

_2208220143515.jpg)

_1908220140538.jpg)

_1908220140539.jpg)

_1908220140541.jpg)

_2208220120922.jpg)

_2208220120923.jpg)

_2208220120924.jpg)

_2508220122958.jpg)

_2508220122959.jpg)

_2508220123000.jpg)