Basic Member

Get a free quote or proposal for

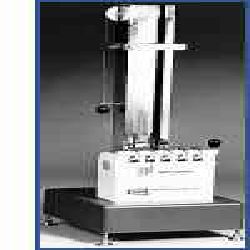

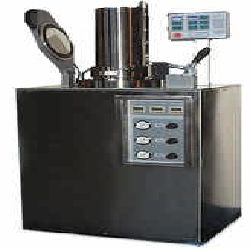

Hot Disintegrator (Latency Refiner)

DESCRIPTION: |

|

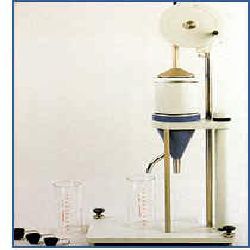

INTRODUCTION: With hot disintegration, pulp shows complete development of strength properties without further treatment. Disintegration time is typically reduced from 15 minutes to 2 minutes. Disintegrating pulp at elevated temperatures reduces latency by removing the stress that is found in fibers that have been disintegrated at lower temperatures. If disintegration is done in cold water, subsequent testing will not show the full strength development of the pulp. Disintegrating the pulp at elevated temperatures and low consistency relaxes the fibers, thus removing the latency. APPLICATIONS: Pulp SPECIFICATIONS: * Meets TAPPI 262 and CPPA C8P * Centrifugal Pump Motor: 240 liters per minute at 3450 rpm * Water temperature: 90-95° C; distilled or demineralized water FEATURES: * 316 Stainless frame * Simple controls |

|

COMMERCIAL DETAILS: |

|

| FOB Price * | Not Mentioned |

| Payment Terms | As mutually agreed |

MORE DETAILS: |

|

| Sample Offered? | Not Applicable |

| Sample Terms | Not Applicable. |

| * Prices are subject to change. Please contact the supplier for the latest price. | |

Veronica Felix

Executive, Testing Machines Inc.

Member Since: Aug 2007

Location ![]()

| Address Line1 | 40 McCullough Drive |

| City | New Castle |

| Postal Code | 19720 |

| State | Delaware |

| Country | United States |

| Region | North America |

Office Schedule

| Working Days | Monday to Friday |

| Working Hours | 9 AM to 5 PM |

- This profile was recently viewed by visitors from Japan, United States, Canada, Germany, Ireland.

Product Listings

by Testing Machines Inc.

Similar Products from Suppliers in Other Countries

Apoaqua Sludge Dewatering Machine for Plastic Granules

Apoaqua's sludge dewatering machine can be used in the sludge treatment process of plastic pellet plants. Plastic pellet factories will inevitably produce wastewater during the production process,...

Inclined Reject Sorter

Inclined Reject Sorter is specially used in Pulping Equipment Machine for Pulp and paper mill in the paper industry.

Reject Separator

Reject separator Applicable process: Used for screening to tail pulp which contain high impurity in waste paper's processing. Size:DIA280-380mm Inlet consistency:1.0-3.5% Production capacity:...

Stock Separator

High consistency operation from 2-5% consistency Energey efficiency Attached cleaner operateds with higher consistency & automatic discharges Increase pulper's capacity

Double Separator

Defivering, cleaning coarse screening, fine screening, and remove small & large unwanted objects. Automatic remove small & large unwanted objects by timed cycle. Increase pulper's capacity High...

Vibratory Screens

Vibration Screens are used for screening of all fibers containing impurities. These screens are used for screening of low as well as high consistency pulp. The screen removes large impurities such...

Raggers

APPLICATION: For removal of spinning contaminants such as wires, rags, strings, plastics by means of ragger rope. FEATURES: *Easy installation with horizontal and vertical type of pulper. ...

Parason Dilution Pulper

Hi-Consistency pulper is connected with dilution pulper. The dilution pulper has due function of separating the plastic and other foreign material as also dilute the high consistency pulp to medium...

Hi-Density Cleaner (Standard)

APPLICATION: Efficient removal of contaminants like sand, glass, chips pins etc from pulp stock. WORKING PRINCIPLE: The tangential inlet accelerates the stock to downward centrifugal motion....

Parason Turbo Separator

APPLICATION: Parason Turbo Separator is a disc screen specially designed for coarse screening of primarily for Pulp strainer with a high trash and flake consent like recycled paper. WORKING...

Find More Products in These Categories

More Product Listings

Looking for Buyers Instead?

Disintegrators Buyers from around the world

Separators Buyers from around the world